Opus 30G

Unit dose of blisters and ampoules

The evolution of a mature solution with 16 years of manufacturing and more than 900 unitizing machines.

-

Produces unit doses of blister pills and ampoules

- High operational efficiency

- Unitarizes with predefined advices and alerts for around 2,000 medications and the possibility of creating new layouts

- Can operate stand-alone or integrate with BC 200 blister cutter

New unwinding system for efficient work with rolls of up to 15,000 units, avoiding frequent roll changes and reducing waste.

New med introduction system, to avoid falling out of the package.

Powerful printing software with up to 2,000 medications, with advices, alerts and ready-made drawings, which integrates with the hospital’s ERP/HIS.

Very small space to operate, easy ergonomics and low noise. It occupies only 62 cm when leaning against the wall.

Features of Opus 30G

- Parameter control, information through 3.7″ color HMI with resistive technology touch screen

- Printer control via dedicated 10.1” touchscreen HMI

- It has 4 disc dimensions, 2 for blisters and 2 for ampoules.

- Equipment has 17 alarms

- Removal of products carried out by a 12-liter removable compartment

- Production up to 2,600 units per hour

- Power consumption 1,300 watts, 220 volts

- Compliance with regulatory requirements of the MTE (NR12 and NR10), ABNT, NBR, and INPAME Standards for Protection of Work on Machines

- Uses biodegradable packaging material*

*Biodegradable input according to Anvisa’s RDC 51 and RDC 105 and ASTM D5511 / ASTM D6601 standards. Check availability.

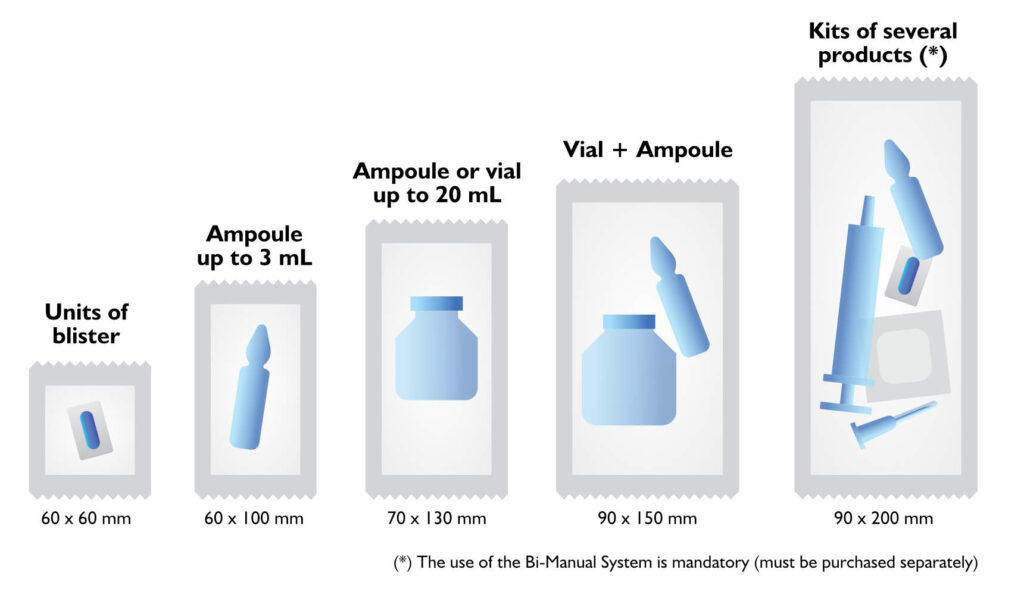

Packaging and material

| Type | Specification | |

|---|---|---|

|

Blister | Max dimensions X and Y: 18 x 30 mm Max. height (H): 9,5 mm |

|

Ampoule and small vials | Max. diameter ⌀: 18,5 mm Max. height (H): 90 mm |

|

Flaconette | Base max. limit (X/Y): 22 x 12 mm Height max. limit (H): 90 mm |

Printing

The thermal transfer printer allows the printing of variable information (texts, logos, codes) through ribbon, directly on the packaging.

- 10.1” touch screen operator interface

- Print Specifications: Full support for TrueType fonts, including non-Roman characters and symbols. Real-time time stamp, automatic date update, barcodes: ITF, Code 39, Code 128, EAN128, EAN 8, EAN 13, UPC A, UPC E, linear RSS, PDF 417, ID Matrix, QR Code and support for Composite RSS barcodes

- Ribbon Width: 53mm

- Software – CoLOS® for creating messages

- Software interface: USB for transferring images, settings and data files

- Real-time HMI access to ribbon status and fault points

- WYSIWYG print preview

| Printer | Print area | Resolution |

|---|---|---|

| Markem Imaje Smartdate X45 | Width up to 53mm Length up to 100mm |

300 dpi |

Software

Opus 5.0 Plus

Controls the printing of 2,000 medicines. Integrates with all ERPs/HIS.

Complete machine with stand-alone or integrated modules for cutting blisters and unit dose of ampoules and blisters (PDF).

Size: 5.72 MB

Register to download